Home / About

FACILITY

KEY STRENGTH

LEAD TIME

LEAD TIME

Recently, we have been able to achieve better shipment times with

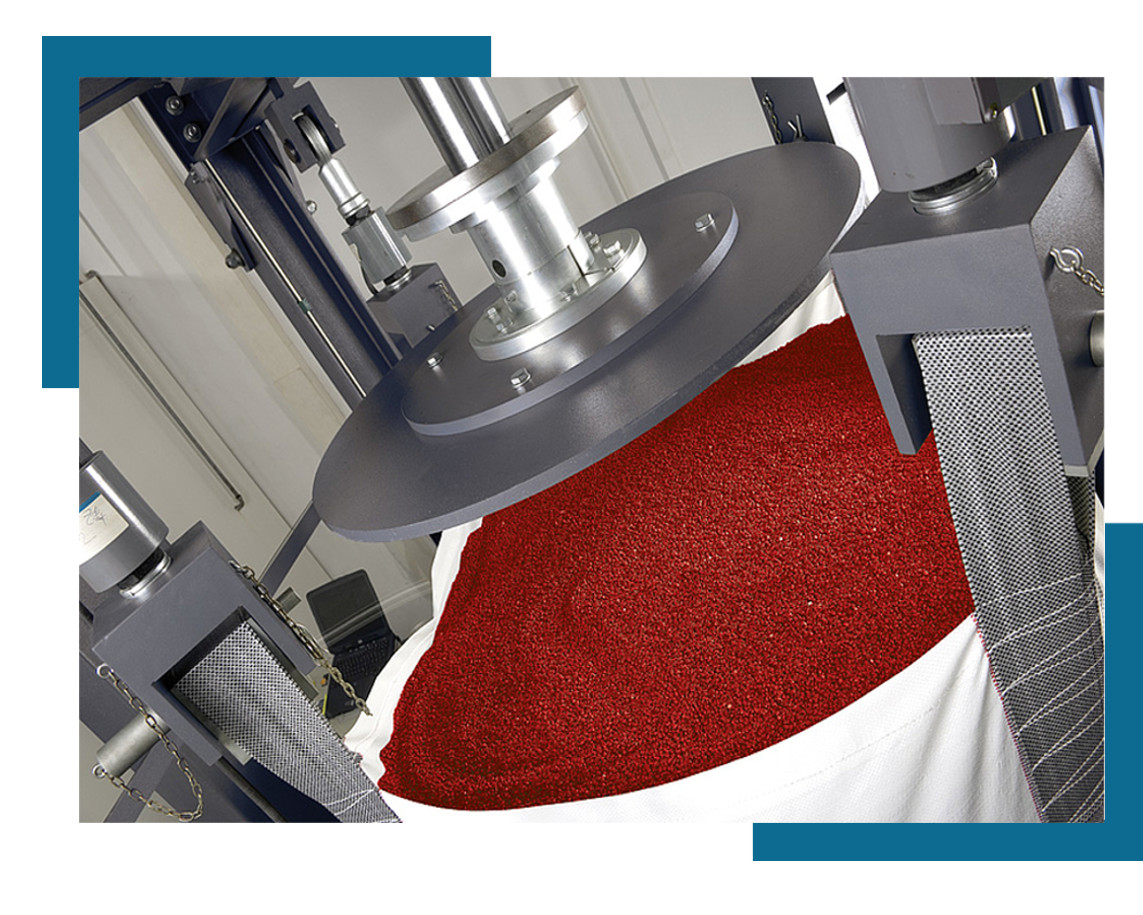

Testing

TO REMAIN COMPETITIVE

TO REMAIN COMPETITIVE

TRACEABILITY

NEW DEVELOPMENTS

NEW DEVELOPMENTS

Copyrights © 2020 Polyspin All rights reserved.